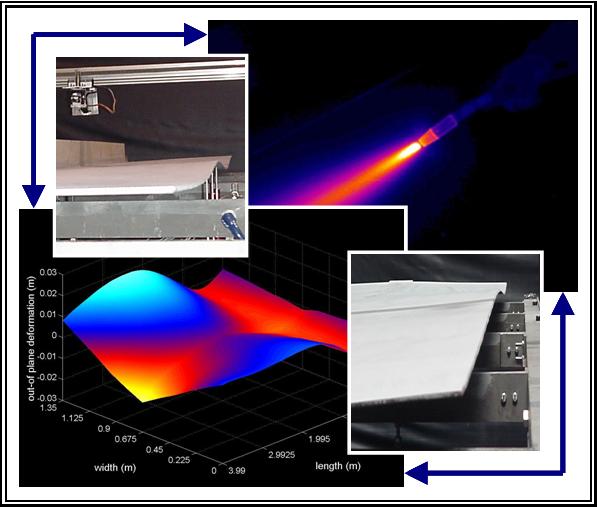

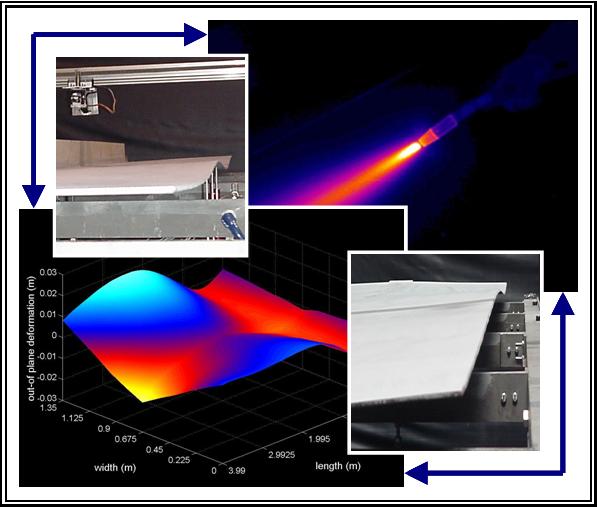

| This research is focused on developing computationally economic, simple to apply, adaptable and robust thermo-mechanical welding finite element models that can be used during the design stages of road, rail, marine and automotive vehicles, together with fluid storage applications. Various numerical finite element thermo-elasto-plastic models and analytical algorithms have been developed and verified by means of full-scale experimental tests. A semi-automated welding rig has been commissioned that is able to measure transient thermal gradients and distortion due to fusion welding of plates and stiffeners. |

|

|

Current research is mainly focused on distortion mitigation fabrication processes to reduce welding residual stresses and distortion. This research forms part of a large consortium including international universities, namely University of Strathclyde together with well established multi-national industries, in particular BVT Surface Fleet Ltd, TWI and Lloyds. The main focus is currently in developing numerical models that are able to predict the residual stresses and distortion due to friction stir welding of steels and identification of optimal design and fabrication procedures adopted for welded assemblies. |